Coffee Maker Leaking Water From the Bottom

As an Amazon Associate I earn from qualifying purchases.

Finding water pooling under your coffee maker is unsettling — and it’s a problem many households experience sooner or later. A coffee maker leaking water from the bottom often looks like a sudden failure, but in most cases, the cause has been developing quietly over time.

Internal seals wear down, hoses loosen, residue builds up, and small positioning mistakes allow moisture to escape where it shouldn’t. Because these issues happen out of sight, the leak usually appears only after damage has already begun.

This guide explains why coffee makers leak from the bottom, how water is meant to move inside the machine, and when a leak is still fixable — versus when it becomes a safety concern.

In This Article

Why Coffee Makers Leak From the Bottom

A bottom leak rarely comes from a single dramatic failure. In most coffee makers, leaking starts when internal components slowly lose their ability to contain heated water under pressure.

Every brewing cycle forces water through hoses, valves, seals, and fittings. Over months or years, heat exposure, mineral deposits, and coffee residue weaken these components. Once resistance builds or seals degrade, water begins escaping downward instead of flowing toward the brew head.

The most common underlying reasons include:

- Worn or hardened internal seals that no longer expand tightly under heat

- Loose internal tubing connections caused by vibration and repeated heating cycles

- Residue buildup that redirects water pressure away from intended channels

- Condensation accumulation inside the housing that eventually drips downward

Because the base of the machine hides these components, leaks are often mistaken for countertop spills or overfilled reservoirs — delaying proper diagnosis.

How Water Is Supposed to Flow Inside a Coffee Maker

To understand why leaks form underneath a coffee maker, it helps to know how water is meant to move through the machine during a normal brew cycle.

Unlike gravity-fed appliances, most coffee makers rely on controlled pressure and heat to move water through narrow internal pathways. When any part of this pathway becomes restricted or weakened, water looks for the easiest exit — often straight down into the base.

Normal Internal Water Pathway

During brewing, water follows a predictable sequence:

- Water leaves the reservoir through an intake valve

- It travels through flexible internal tubing toward the heating element

- Heated water expands and gains pressure

- Pressure pushes water upward to the brew head

- Water exits through the spray head and onto the coffee grounds

As long as tubing, seals, and fittings remain intact, this system stays closed and controlled.

What Changes When a Leak Starts

When internal components degrade, water no longer follows the intended path. Instead, pressure escapes through the weakest point — usually a seal, hose joint, or valve near the base.

Common pressure-disrupting conditions include:

- Mineral deposits narrowing internal tubing

- Heat-hardened seals losing elasticity

- Loose hose clamps from vibration

- Micro-cracks in plastic fittings

Once pressure drops or redirects, water settles inside the housing and eventually drips out from the bottom — even though the reservoir itself may not be leaking.

Once pressure drops or water is redirected away from its intended path, moisture begins collecting inside the coffee maker’s housing. Because this happens internally, leaks often go unnoticed until water starts dripping from the bottom of the machine.

At this stage, the problem is no longer cosmetic. Internal leaks allow water to pool near electrical components, increasing the risk of corrosion, malfunction, and long-term damage.

Next, we’ll identify the exact internal components most commonly responsible for bottom leaks — and explain why these parts fail more often than others.

Next, we’ll identify the exact internal components most likely responsible for bottom leaks — and why they fail more often than others.

The Most Common Internal Leak Points

When a coffee maker leaks from the bottom, the source is almost always an internal component failure rather than a visible crack or spill. Water escapes from parts designed to handle heat and pressure — once those parts degrade, leaks become unavoidable.

These failures typically develop gradually, which is why many bottom leaks appear “sudden” even though damage has been building for months.

Failed Internal Seals and Gaskets

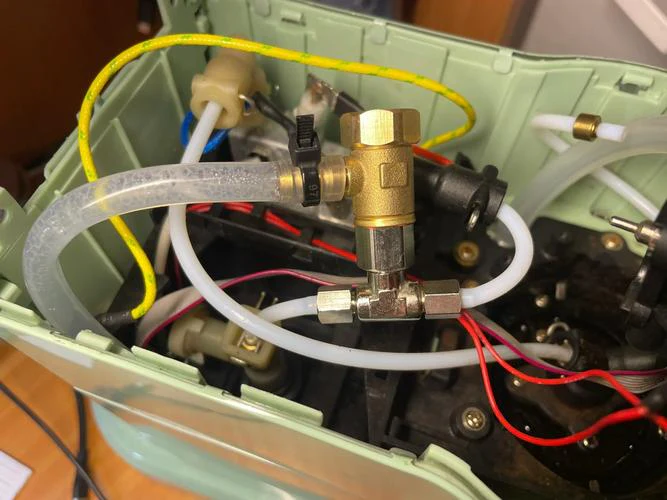

Seals and gaskets sit at connection points where tubing meets heating chambers, valves, or pumps. Their job is simple: keep pressurized hot water contained as it moves through the system.

Over time, heat exposure causes rubber and silicone seals to harden, crack, or lose flexibility. Once this happens, water begins seeping past the seal and collecting inside the machine.

Because the leak occurs internally, the first visible sign is often water pooling underneath the coffee maker rather than dripping from the top.

Cracked or Degraded Internal Tubing

Most coffee makers rely on narrow plastic or silicone tubes to transport water. These tubes are exposed to repeated heating and cooling cycles, which gradually weaken their structure.

Small splits or pinhole cracks allow water to escape under pressure. Instead of flowing upward to the brew head, water leaks downward into the base of the machine.

This type of leak often worsens quickly once it starts, especially during longer or hotter brew cycles.

Loose Hose Clamps and Fittings

Internal hoses are secured using clamps and fittings designed to remain tight under vibration and heat. With regular use, these connections can loosen slightly.

Even a minor gap at a fitting allows water to escape during brewing. Because the housing hides the leak, moisture continues accumulating until it finds the lowest exit point — the bottom.

Why These Components Fail More Often Than Others

Internal leak points fail first because they experience the most stress. They handle hot water, pressure changes, vibration, and mineral exposure simultaneously.

Once one component weakens, surrounding parts are exposed to additional moisture, accelerating further failures. This is why bottom leaks often progress from minor drips to persistent pooling if left unresolved.

In the next section, we’ll look at how storage habits and counter placement quietly contribute to internal leaks — even when the coffee maker itself appears undamaged.

How Storage and Placement Contribute to Leaks

Bottom leaks are not always caused by internal failures alone. In many cases, how a coffee maker is stored, positioned, or used on the counter quietly accelerates seal damage and internal stress.

These issues develop slowly and often go unnoticed because the machine continues brewing normally — until water begins escaping from the base.

Why Counter Placement Matters More Than You Think

Coffee makers rely on stable, level surfaces to keep internal water pathways aligned. When a machine sits on an uneven counter, tilted surface, or soft mat, internal pressure shifts toward weaker seals.

Over time, this constant imbalance can:

- Stress rubber gaskets and O-rings

- Loosen internal hose connections

- Encourage slow seepage toward the bottom housing

Even small, repeated shifts — such as sliding the machine daily or bumping it during refills — can compound this stress.

How Poor Storage Accelerates Internal Damage

Improper storage is another silent contributor to bottom leaks. Coffee makers stored in tight cabinets, damp areas, or crowded counters retain moisture and heat longer than intended.

Trapped moisture weakens seals and promotes residue buildup inside internal channels, especially when combined with heat from frequent brewing cycles.

Why Heat and Moisture Are a Dangerous Combination

Coffee makers generate heat and steam by design. When that heat cannot dissipate properly due to tight placement or poor ventilation, internal components stay warm for longer periods.

This leads to:

- Faster degradation of rubber seals

- Expansion and contraction of plastic housings

- Micro-gaps forming around hose fittings

Once those gaps appear, water naturally seeks the lowest exit point — which is why leaks often show up underneath the machine.

Why These Problems Are Often Misdiagnosed

Because storage- and placement-related leaks develop gradually, many users assume the machine is simply “wearing out.” In reality, preventable environmental stress is often the trigger.

Addressing placement and airflow early can stop minor seepage before it becomes a recurring bottom leak or electrical hazard.

In the next section, we’ll look at when a bottom leak stops being a maintenance issue — and becomes a genuine safety concern.

When a Bottom Leak Becomes a Safety Risk

Not every bottom leak is immediately dangerous — but some warning signs mean the coffee maker should no longer be used until the issue is resolved.

Once water escapes the internal pathway and reaches electrical components, the problem shifts from inconvenience to safety concern.

Signs a Bottom Leak Is No Longer Just a Maintenance Issue

Some symptoms indicate that water is no longer confined to safe internal channels and may be interacting with electrical components.

- Water pooling directly beneath the power cord or plug area

- Intermittent power loss during brewing

- Burning or hot plastic smells

- Visible moisture inside the base housing

These signs suggest internal insulation, wiring, or heating components may already be compromised.

Why Electrical Exposure Changes Everything

Coffee makers combine water, heat, and electricity in a compact space. When internal seals fail, water naturally moves downward — straight toward wiring and control boards.

Once moisture reaches these areas, corrosion begins quickly. Even if the machine appears to function afterward, damage may already be progressing internally.

Why “Drying It Out” Is Not a Reliable Fix

Some users attempt to dry a leaking coffee maker and continue using it. While surface moisture may evaporate, internal corrosion and residue remain.

This creates unpredictable behavior, including:

- Delayed electrical failure

- Sudden shutdowns mid-brew

- Recurring leaks that worsen over time

At this stage, the issue is no longer about cleaning or tightening parts — it’s about preventing unsafe operation.

When Replacement Becomes the Safer Choice

If a bottom leak repeatedly returns after basic maintenance — or appears alongside electrical symptoms — replacement is usually the safest option.

At that point, continued use risks:

- Permanent electrical damage

- Higher repair costs than replacement

- Unexpected safety hazards in daily use

Bottom leaks are rarely random — they’re usually the result of internal wear, pressure imbalance, or long-term environmental stress.

In the final section, we’ll answer common questions about bottom leaks, safety concerns, and how to decide whether repair or replacement makes more sense.

Frequently Asked Questions

Why is my coffee maker leaking water from the bottom?

Bottom leaks usually occur when internal seals, hoses, or valves deteriorate. Over time, heat, mineral buildup, and pressure weaken these components, allowing water to escape downward into the base.

Is a coffee maker leaking from the bottom dangerous?

It can be. If water reaches electrical components, the risk increases significantly. Leaks near the base or power cord should always be treated as a safety concern and addressed immediately.

Can mineral buildup cause a coffee maker to leak?

Yes. Mineral deposits restrict internal water flow, increasing pressure inside tubing and valves. This extra pressure can force water past weakened seals, leading to bottom leaks.

Will descaling fix a coffee maker leaking from the bottom?

Descaling can help if the leak is pressure-related and caused by mineral buildup. However, if seals or internal hoses are damaged, descaling alone will not stop the leak.

Can poor storage or placement cause bottom leaks?

Yes. Tight spaces restrict airflow and trap heat, accelerating seal degradation. Improper placement can also cause internal water to shift toward weak points, increasing leak risk.

Should I keep using a coffee maker that leaks occasionally?

No. Even small, intermittent leaks can worsen quickly. Continued use may cause electrical damage or make repairs impossible.

How do I know if my coffee maker should be replaced instead of repaired?

If leaks return shortly after cleaning, appear alongside electrical issues, or occur in multiple areas, replacement is usually the safer and more reliable option.

Amazon and the Amazon logo are trademarks of Amazon.com, Inc, or its affiliates.