- You are here:

- Home »

- Kitchen Tips »

- What Happens If You Never Descale a Coffee Maker?

What Happens If You Never Descale a Coffee Maker?

As an Amazon Associate I earn from qualifying purchases.

Coffee makers rarely stop brewing without warning. In most homes, the problem develops slowly — long before the machine refuses to brew at all.

Mineral deposits from hard water, coffee oil residue, airflow restrictions, and daily usage habits gradually interfere with internal water flow and temperature control. These changes often go unnoticed until brewing suddenly fails.

This article explains why coffee makers stop brewing over time, what internal processes are usually responsible, and how to recognize early warning signs before performance drops completely.

If your coffee maker has already stopped brewing, follow our step-by-step repair guide here: How to Fix a Coffee Maker That Won’t Brew.

In This Article

- Why Brewing Problems Often Go Unnoticed

- What Disrupts Water Flow Inside Coffee Makers

- Why Mineral Buildup Eventually Stops Brewing

- How Daily Habits Quietly Accelerate Brewing Failure

- How Brewing Problems Can Be Prevented

- When a Coffee Maker Is Beyond Repair

- When Maintenance Still Helps — and When It No Longer Does

- Frequently Asked Questions

Why Brewing Problems Often Go Unnoticed

Most coffee makers don’t fail suddenly. Instead, performance declines gradually as internal conditions change with everyday use. Because brewing still “sort of works” for weeks or months, early warning signs are easy to ignore.

In many cases, the machine continues turning on normally, heating water, and making familiar sounds — even as internal pathways become restricted. By the time brewing stops entirely, the underlying issue has usually been developing for a long time.

Some of the most commonly overlooked early conditions include:

- Partial mineral buildup that slows water movement without stopping it

- Coffee oil residue coating spray heads and internal valves

- Minor airflow restrictions caused by tight counter placement

- Infrequent cleaning habits that allow residue to accumulate unnoticed

Because these changes happen slowly, many people assume weaker coffee, longer brew times, or inconsistent temperature are “normal aging” rather than signs of developing failure.

What Disrupts Water Flow Inside Coffee Makers

At its core, brewing depends on one simple process: water must move smoothly from the reservoir, through internal tubing, into the heating chamber, and out through the brew head at consistent pressure.

When that movement is disrupted — even slightly — brewing performance begins to decline. In many cases, the coffee maker still turns on and heats, but water no longer reaches the brew head efficiently enough to complete a full cycle.

Water flow problems tend to develop internally, out of sight, and are often mistaken for electrical or “old machine” issues.

Clogged Brew Heads and Spray Nozzles

The brew head is one of the most vulnerable areas inside a coffee maker. It contains small spray openings designed to distribute hot water evenly over the coffee grounds.

Over time, these openings narrow as coffee oils and fine mineral particles accumulate. Even partial obstruction reduces water pressure enough to interrupt brewing.

Common symptoms of brew head restriction include:

- Water dripping slowly instead of spraying

- Uneven saturation of coffee grounds

- Brewing that starts but stops mid-cycle

Because the machine still powers on normally, this type of blockage is often misdiagnosed as a pump or heating failure.

Internal Tube Narrowing From Scale and Residue

Inside every coffee maker are narrow tubes that transport water from the reservoir to the heating element. These passages are especially sensitive to mineral buildup from hard water.

As scale accumulates, internal tube diameter gradually decreases. The coffee maker compensates at first by increasing brew time, but eventually pressure drops below the threshold required to sustain brewing.

This explains why many machines show a slow decline in performance before brewing stops entirely.

Airlocks After Refilling or Storage

Airlocks occur when air becomes trapped inside the intake system, preventing water from being pulled into the internal tubing. This often happens after the reservoir runs completely dry or is removed and reinserted.

When an airlock forms:

- The machine may sound like it’s running normally

- Little or no water reaches the brew head

- Brewing may stop without visible error indicators

Airlocks are temporary but can mimic more serious internal failures if not recognized.

Why These Issues Escalate Instead of Resolving Themselves

Once water flow becomes restricted, heat and residue accumulation accelerate the problem. Slower movement allows minerals to settle more easily, while reduced pressure prevents self-clearing of small obstructions.

This is why brewing issues rarely improve on their own — and why early intervention matters.

In the next section, we’ll look at the single most common long-term contributor to brewing failure: mineral buildup from hard water, and why it eventually stops brewing altogether.

Why Mineral Buildup Eventually Stops Brewing

Mineral buildup is the most common long-term reason coffee makers lose brewing ability. Unlike visible clogs or temporary airlocks, mineral deposits accumulate quietly inside internal tubing, valves, and heating components.

Every time water is heated, dissolved minerals such as calcium and magnesium are left behind. In areas with hard water, this process happens faster — but even soft water contributes to gradual scale formation over time.

At first, these deposits are thin and barely noticeable. As they thicken, they begin interfering with both water flow and temperature regulation.

How Scale Changes the Way a Coffee Maker Works

A coffee maker is designed to move water at a specific speed and pressure. Mineral scale disrupts this balance by narrowing internal pathways and insulating heating surfaces.

As buildup increases, the machine must work harder to heat and move water. This leads to:

- Longer brew times

- Lower water temperature

- Incomplete extraction

- Inconsistent brewing cycles

Eventually, the machine can no longer maintain the conditions needed to brew at all.

Why Brewing Failure Happens Suddenly

One of the most confusing aspects of mineral buildup is how abruptly brewing failure seems to occur. In reality, the problem develops gradually — but reaches a tipping point.

Once internal tubing becomes sufficiently narrowed, water pressure drops below the minimum threshold required to activate normal brewing. At that stage, the coffee maker may:

- Turn on without brewing

- Start a cycle and shut off early

- Heat without releasing water

Because the failure feels sudden, many users assume the machine is broken beyond repair — even though the underlying cause is accumulated scale.

Why Skipping Descaling Makes Damage Worse

Descaling is the only process that actively dissolves mineral deposits inside a coffee maker. When descaling is skipped, scale continues to harden and bond to internal surfaces.

Over time, untreated buildup can:

- Corrode internal valves

- Overheat heating elements

- Trigger automatic safety shutoffs

- Shorten overall appliance lifespan

This is why coffee makers that are never descaled often fail years earlier than expected — even if they were otherwise well cared for.

Why Rinsing Alone Is Not Enough

Many people believe that running plain water through a coffee maker cleans internal buildup. Unfortunately, water alone cannot dissolve hardened mineral deposits.

In fact, repeated brewing without descaling often accelerates scale formation by continuously heating mineral-rich water without removing residue.

By the time brewing performance noticeably declines, buildup has usually progressed beyond what simple rinsing can address.

In the next section, we’ll look at how daily habits and placement decisions quietly accelerate brewing failure — even in machines that are cleaned occasionally.

How Daily Habits Quietly Accelerate Brewing Failure

Not all brewing problems come from neglect. In many homes, coffee makers fail early because of small daily habits that seem harmless but compound over time.

These habits don’t cause immediate breakdowns. Instead, they slowly increase heat stress, moisture retention, and internal residue — setting the stage for brewing failure even in machines that are occasionally cleaned.

Leaving Water Sitting in the Reservoir

Keeping water in the reservoir between uses is one of the most common habits that accelerates mineral buildup. When water sits stagnant, minerals settle and begin bonding to internal surfaces.

Each reheating cycle reinforces this process, allowing scale to harden faster than it would with fresh water refills.

Over time, this habit contributes to uneven heating and restricted flow — even if the coffee maker appears to function normally for months.

Using the Same Filter Without Proper Cleaning

Reusable filters and baskets are designed for convenience, but they require regular cleaning. Coffee oils cling to mesh and plastic surfaces, forming sticky layers that trap fine particles.

As residue builds, water struggles to pass through at the intended rate. This slows brewing and increases internal pressure elsewhere in the system.

Eventually, the machine compensates by reducing flow or shutting down early to prevent damage.

Overfilling or Compacting Coffee Grounds

Using too much coffee or compressing grounds in the filter basket increases resistance during brewing. While this may seem like a way to get stronger coffee, it strains the system.

Repeated resistance forces water to back up into internal channels, increasing residue accumulation and accelerating wear on valves and seals.

This habit is especially damaging in compact or budget coffee makers that lack pressure regulation safeguards.

Why Placement and Airflow Matter More Than Expected

Where a coffee maker sits on the counter plays a larger role in its lifespan than most people realize. Tight spaces trap heat and moisture around the machine.

Poor airflow prevents internal components from cooling properly between cycles. Over time, this leads to:

- Heat stress on electrical components

- Moisture buildup inside housing panels

- Faster degradation of seals and tubing

These conditions don’t cause immediate failure — but they shorten the window before brewing problems appear.

Why These Issues Often Go Unnoticed

Daily habit-related damage rarely produces obvious warning signs. Brewing may remain consistent for long periods before suddenly becoming unreliable.

Because the decline is gradual, many users attribute brewing failure to age or assume the machine is defective — without realizing that preventable conditions played a major role.

In the final section, we’ll look at how to recognize when maintenance can still reverse brewing problems — and when a coffee maker has reached the point where repair no longer makes sense.

How Brewing Problems Can Be Prevented

Most coffee makers don’t fail because of a single mistake. Brewing problems usually develop when small maintenance steps are skipped repeatedly over time.

Preventing brewing failure isn’t about constant deep cleaning. It’s about reducing the conditions that allow mineral buildup, residue accumulation, and heat stress to accelerate.

Why Prevention Works Better Than Repair

Once internal pathways become heavily restricted, restoring full brewing performance becomes harder. Preventive habits slow down this process long before symptoms appear.

Simple routines — like refreshing reservoir water, avoiding prolonged heat buildup, and descaling before performance drops — keep internal systems operating within normal limits.

Maintenance Habits That Actually Matter

- Replacing reservoir water instead of letting it sit between uses

- Rinsing removable parts before residue hardens

- Allowing airflow around the machine after brewing

- Descaling before brew time noticeably slows

These habits don’t prevent all wear, but they significantly delay the point where brewing problems begin interfering with daily use.

Prevention works best when brewing still feels “normal” — not after performance has already collapsed.

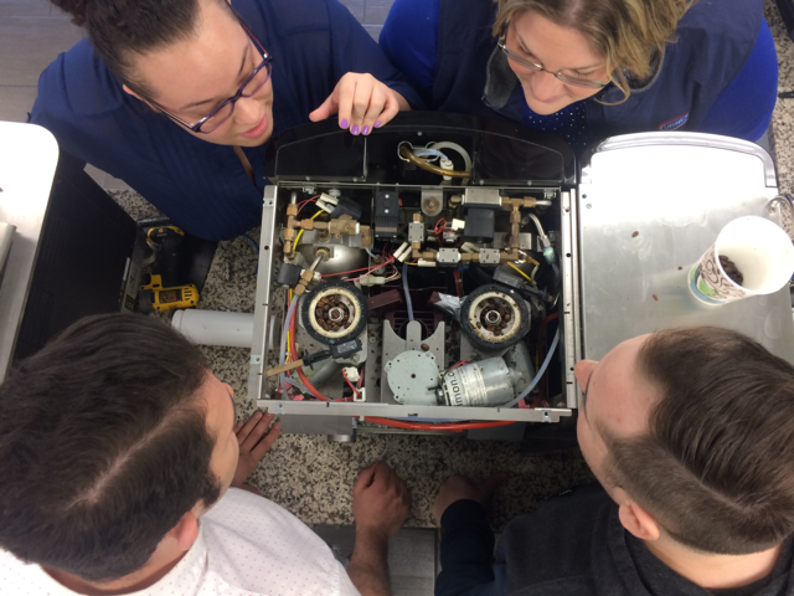

When a Coffee Maker Is Beyond Repair

Not every coffee maker that struggles to brew can — or should — be saved. At a certain point, maintenance stops delivering meaningful improvements.

Understanding when a machine has crossed that threshold helps avoid repeated frustration and wasted effort.

Signs Internal Wear Has Replaced Buildup

Brewing issues caused by buildup usually improve after cleaning or descaling. When problems return quickly or worsen, internal wear is often the real cause.

- Brewing stops even after thorough descaling

- Water heats inconsistently or not at all

- Cycles shut off randomly without warning

- Electrical smells, leaks, or breaker trips occur

Why Repairs Stop Making Sense

Once pumps, heating elements, or electronic controls degrade, cleaning no longer restores reliable operation. Problems may temporarily disappear, but they return faster each time.

At this stage, continued maintenance often costs more time and frustration than replacement.

Making a Practical Decision

If maintenance restores normal brewing for months, it’s worth continuing. If problems reappear within weeks, replacement becomes the more stable and safer option.

Replacing a failing coffee maker at the right time prevents wasted coffee, inconsistent results, and unexpected electrical issues.

When Maintenance Still Helps — and When It No Longer Does

This section isn’t about diagnosing failure — it’s about deciding what makes practical sense once problems begin repeating.

Not every coffee maker that struggles to brew is beyond saving. In many cases, proper maintenance can restore performance — but there is a clear point where continued fixes stop being practical.

Understanding where your machine falls on that spectrum helps avoid wasted effort, unnecessary frustration, and repeated brewing failures.

When Maintenance Is Still Worth Doing

Maintenance usually delivers real results when brewing problems are caused by buildup rather than wear. If your coffee maker shows the following signs, cleaning and preventive care are still effective:

- The machine heats but brews slowly or inconsistently

- Brewing performance fluctuates rather than failing completely

- Problems improve temporarily after cleaning or descaling

- No electrical smells, leaks, or power interruptions are present

In these cases, mineral deposits, residue, or airflow issues are usually responsible. Addressing those factors can stabilize brewing and extend the machine’s usable life.

Signs Maintenance Is No Longer Enough

Some symptoms indicate that internal components have degraded beyond what cleaning can fix. These problems tend to return quickly — or worsen — even after thorough maintenance.

- The coffee maker no longer heats water consistently

- Brewing stops mid-cycle without warning

- Electrical issues such as tripped breakers occur

- Burning smells or visible internal damage appear

At this stage, internal pumps, heating elements, or electronic controls are often failing. Continued use may become unsafe or unreliable.

Why Repeated Failures Matter

When brewing problems return shortly after cleaning, it usually means the underlying issue is no longer surface-level. Internal wear creates conditions that allow buildup to recur faster each time.

This creates a cycle where maintenance provides only brief relief before performance drops again — signaling that replacement is the more stable solution.

Making a Practical Decision

A good rule of thumb is to weigh effort against reliability. If maintenance restores consistent brewing for months at a time, it’s worth continuing. If problems return within weeks, the machine is nearing the end of its practical lifespan.

Replacing a failing coffee maker at the right time often prevents wasted ingredients, daily frustration, and unexpected electrical issues.

Final Takeaway

Coffee makers rarely fail overnight. Brewing problems almost always develop gradually through buildup, heat stress, airflow restrictions, and daily habits.

By understanding how these factors interact — and recognizing early warning signs — you can often delay or prevent complete brewing failure.

When maintenance still works, it’s worth doing. When it no longer does, replacing the machine becomes the safer and more reliable choice.

Frequently Asked Questions

Why do coffee makers usually stop brewing gradually instead of suddenly?

Most coffee makers don’t fail overnight. Brewing performance declines slowly as mineral deposits, coffee oils, and heat stress interfere with internal water flow and temperature regulation. The machine often continues working until pressure or heat drops below functional thresholds.

Can a coffee maker lose performance even if it’s cleaned occasionally?

Yes. Occasional surface cleaning helps, but it doesn’t remove mineral buildup inside internal tubing and heating components. Without regular descaling and proper airflow, internal restrictions continue to develop over time.

Is mineral buildup really the main reason coffee makers stop brewing?

In most cases, yes. Mineral deposits from hard water gradually narrow internal water pathways and insulate heating elements. This reduces both water pressure and temperature until the machine can no longer sustain a full brewing cycle.

Do coffee makers show warning signs before brewing stops completely?

Often they do. Slower brew times, weaker coffee, inconsistent temperature, unusual noises, or frequent mid-cycle shutoffs usually appear weeks or months before brewing fails entirely.

Can poor placement on the counter affect coffee maker performance?

Yes. Tight spaces restrict airflow and trap heat and moisture around the machine. Over time, poor ventilation accelerates internal wear, residue buildup, and electrical stress, shortening the coffee maker’s lifespan.

Does leaving water in the reservoir cause damage?

Leaving water in the reservoir allows minerals to settle and bond to internal surfaces. Reheating stagnant water repeatedly accelerates scale formation and increases the risk of uneven heating and restricted flow.

Is rinsing with plain water enough to keep a coffee maker healthy?

No. Plain water cannot dissolve hardened mineral deposits. While rinsing helps remove loose residue, only descaling solutions actively break down scale inside internal tubing and heating components.

How often should a coffee maker be descaled to prevent brewing failure?

In hard-water areas, descaling every 4–6 weeks is recommended. In softer-water regions, every 2–3 months is usually sufficient. Frequent use may require more regular descaling.

When does maintenance stop being effective for a coffee maker?

Maintenance becomes less effective when heating elements, pumps, or electronic controls begin to fail. If brewing problems return quickly after cleaning or descaling, internal wear is usually the cause.

Is it better to fix or replace a coffee maker that struggles to brew?

Newer machines often benefit from maintenance and preventive care. Older or frequently failing coffee makers are usually more cost-effective and safer to replace, especially if electrical or heating issues are present.

Amazon and the Amazon logo are trademarks of Amazon.com, Inc, or its affiliates.